JFE Steel Develops JNRF™ Silicon-gradient Steel Sheet for High-speed Motors

-

Minimizes high-frequency iron loss

-

Improves high magnetic flux density

JFE Steel Corporation announced today its recently developed JNRF™ silicon-gradient steel sheet for use in high-speed motors, which the company produces using proprietary chemical vapor deposition (CVD) technology for continuous siliconizing. The new material reduces high-frequency iron loss and improves magnetic flux density, thereby helping to increase motor torque and significantly improve efficiency for energy conservation.

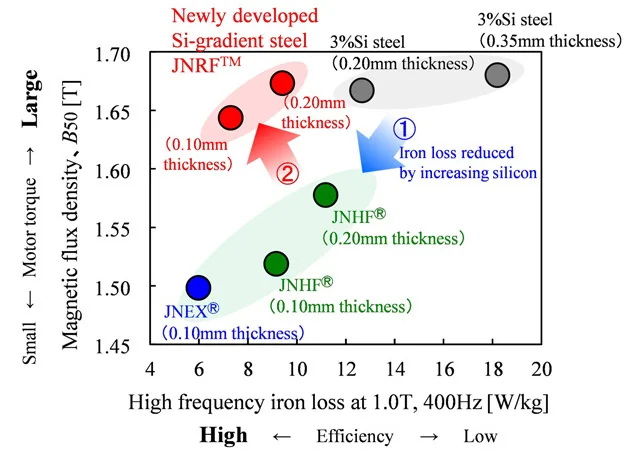

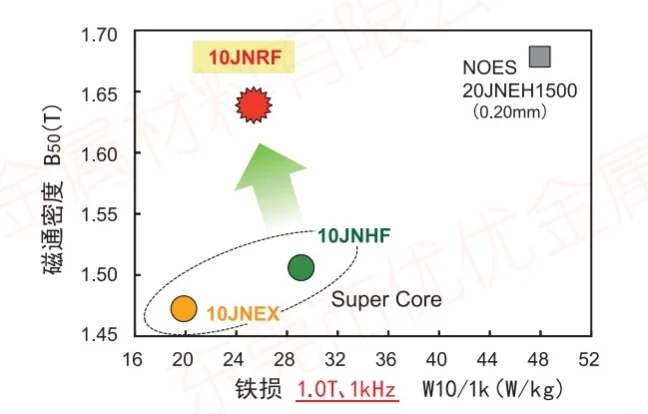

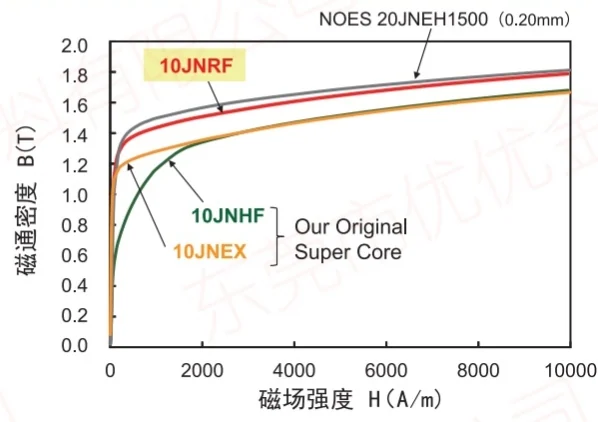

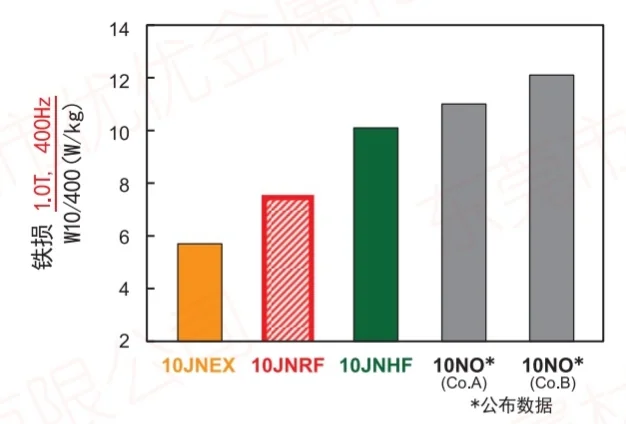

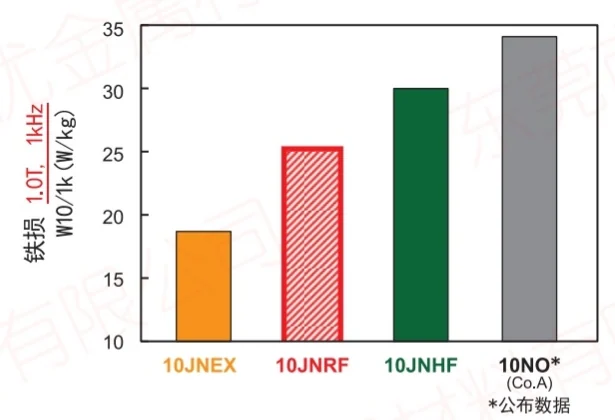

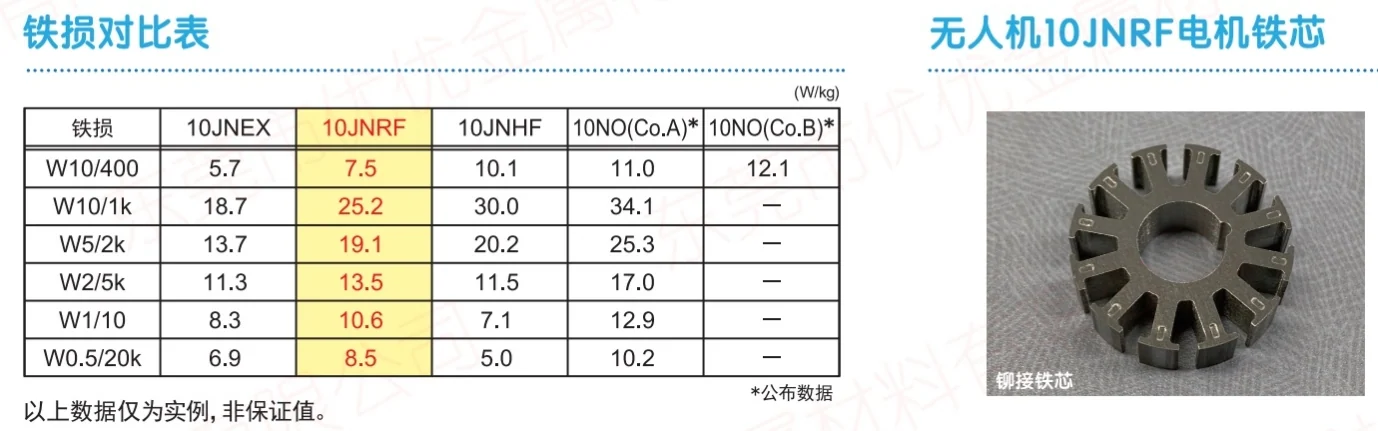

Electrical steel sheets4, which are used widely as an iron core material for electrical equipment such as motors and transformers, are a key material governing the performance of electrical equipment. In recent years, efforts to increase driving frequency5 for the downsizing of electrical equipment have created needs to reduce iron loss in electrical steel sheets used in applications involving high-frequency drive. Silicon increases the electrical resistance of steel, so increasing the amount silicon helps to reduce iron loss in the high frequency range. JFE Steel developed a proprietary technology for CVD continuous siliconizing, and then used this process to produce JNEX Core®, a high-silicon (6.5%) steel sheet, and JNHF Core®, a silicon-gradient steel sheet with increased silicon concentration in its surface layer, both of which will enable JFE Steel customers to develop higher-quality products (Fig. 1①).

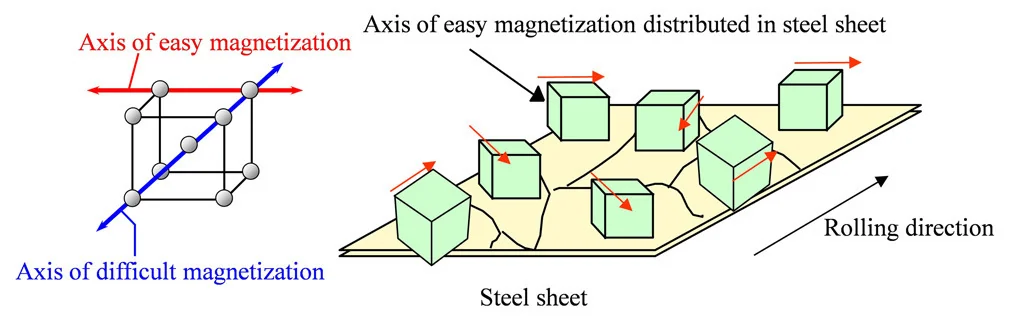

In high-speed motor applications, there are growing demands for reduced iron loss due to high-frequency drive and increased magnetic flux density for higher torque. In response, JFE Steel launched a plan to enhance its lineup of electrical steel sheet products. The solution was to control silicon concentration distribution by optimizing the siliconizing amount and diffusion conditions (Fig. 2) and control crystal orientation (Fig. 3).

The successful result of these efforts is JFE Steel’s new JNRF™ silicon-gradient steel sheet for high-speed motors. JNRF™ helps to significantly increase motor efficiency for energy conservation while maintaining magnetic flux density (torque) equivalent to that of conventional non-oriented electrical steel sheets (3% silicon steel sheets) (Fig. 1②).

*Iron's ease of magnetization depends on crystal orientation. An easily magnetized(high magnetic-flux density) material can be produced by controlling orientation inparallel with the sheet surface.

Moving forward, JFE Steel will endeavor to expand the applications for its electrical steel sheet products to help realize more compact and higher speed motor designs, such as drive motors for electric vehicles, motors for consumer electronics and drone motors, thereby meeting customer needs for extra efficient and compact electrical equipment in an increasingly sustainable world.

The chemical vapor deposition (CVD) process technology increases silicon concentration in steel. CVD, which is performed in a steel strip annealing line, causes a reaction between steel strips and silicon tetrachloride (SiCl4) gas in a furnace while continuously passing the steel strips through the furnace.

Iron loss refers to energy, mainly heat, lost when an iron core is excited by an alternating current. The energy loss that occurs when the iron core is excited at high frequency is called a high-frequency iron loss. The efficiency of high-speed motors increases as high-frequency iron loss is reduced.

Magnetic flux density, which indicates a material’s ease of magnetization, raises electromagnetic strength as density increases. In motors, larger torque (power) can be achieved with materials that offer high magnetic flux density.

Electrical steel sheet (or “silicon steel sheet”) is obtained by adding silicon to iron. Thin sheets used widely as iron core materials in equipment such as motors and transformers are first laminated with an insulation coating.

In electrical equipment, the driving frequency is the number of oscillations per second of the current, voltage, etc. Ordinarily, driving frequency increases with motors that drive at high rotational speeds.

JNEX Core® and JNHF Core® and JNRF Core® are registered trademarks of JFE Steel Corporation.

JFE Super Core jnrf the magnetic flux density is higher and the iron loss is lower

JFE Super Core jnrf magnetic flux density is higher