Introduction: In motor manufacturing, precise laminated lamination production plays a key role in the performance and quality of the motor. Backlack is an innovative adhesive that can help you achieve high-precision production of motor stator and rotor laminates, thereby improving motor performance.

1. The importance of lamination of motor stator and rotor

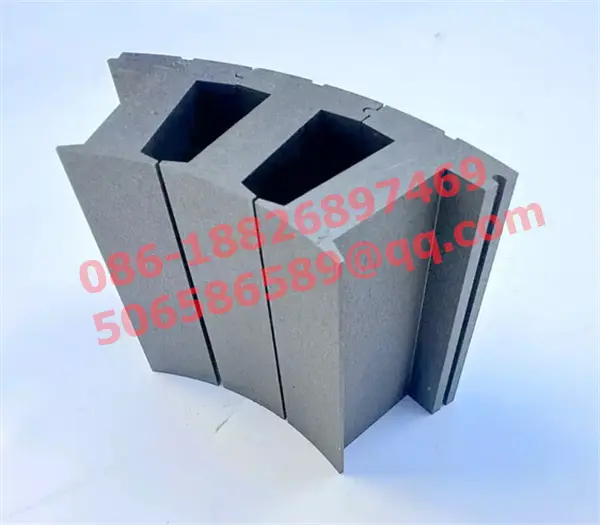

The motor stator and rotor are the main components of the motor, and their quality and performance directly affect the overall performance of the motor. During the motor manufacturing process, the stator and rotor usually undergo a lamination process to form a precise magnetic circuit and increase the power density of the motor. Therefore, choosing the right adhesive is critical to achieving high-precision lamination stack-ups.

2. Application of backlack in motor stator and rotor lamination

Backlack is a new adhesive designed for high-precision lamination stack production. In motor manufacturing, Backlack can be applied to the following scenarios:

2.1. Stator core bonding

Backlack can ensure that the stator core maintains a stable bonding effect under high temperature and high pressure environments, thereby improving the performance and efficiency of the motor.

2.2. Rotor core bonding

Backlack can provide a precise bonding effect during the lamination process of the rotor core, ensuring the stability of the rotor magnetic circuit and reducing the vibration and noise of the motor.

2.3. Magnetic steel bonding

Backlack can be used to bond magnetic materials, such as magnetic steel, to improve the magnetic performance and magnetic density of the motor.

3. Advantages of Backlack

Compared with other traditional adhesives, Backlack has the following advantages:

3.1. High precision

Backlack can achieve extremely high-precision lamination, thereby improving the magnetic circuit accuracy and performance of the motor.

3.2. Strong bonding strength

Backlack has excellent bonding strength and can maintain a stable bonding effect even in high temperature and high pressure environments.

3.3. Flexibility

Backlack can be applied to various magnetic materials and processes to meet the needs of different motor designs.

3.4. High temperature resistance

Backlack can still maintain excellent adhesive properties in high temperature environments and is suitable for the baking process of motor manufacturing.

4. Conclusion

By using Backlack adhesives, you can achieve high-precision bonding in motor stator and rotor lamination lamination production, thereby improving motor performance and quality. Choose Backlack as your adhesive to make your motor manufacturing process more sophisticated and create more competitive advantages for your motor products.

You might also be interested in