As the heart of modern industry, the motor's stator and rotor lamination stacks in its internal structure are indispensable key components. Although they are both important parts of the motor, there are significant differences in structure, function and production process. This article will elaborate on these differences and explore their production processes and applications.

Differences between stator and rotor lamination stacks

1. Structure:

|

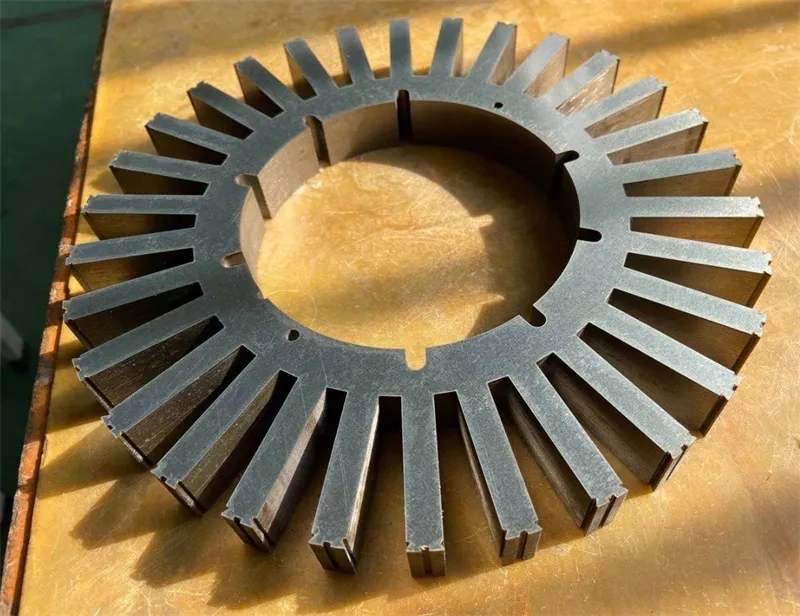

Stator lamination stack |

Usually made of multiple silicon steel sheets stacked together to form a cylindrical whole. There are slots inside it for embedding winding coils. The main function of the stator lamination stack is to provide a stable magnetic field so that the rotor can rotate in it. |

|---|---|

|

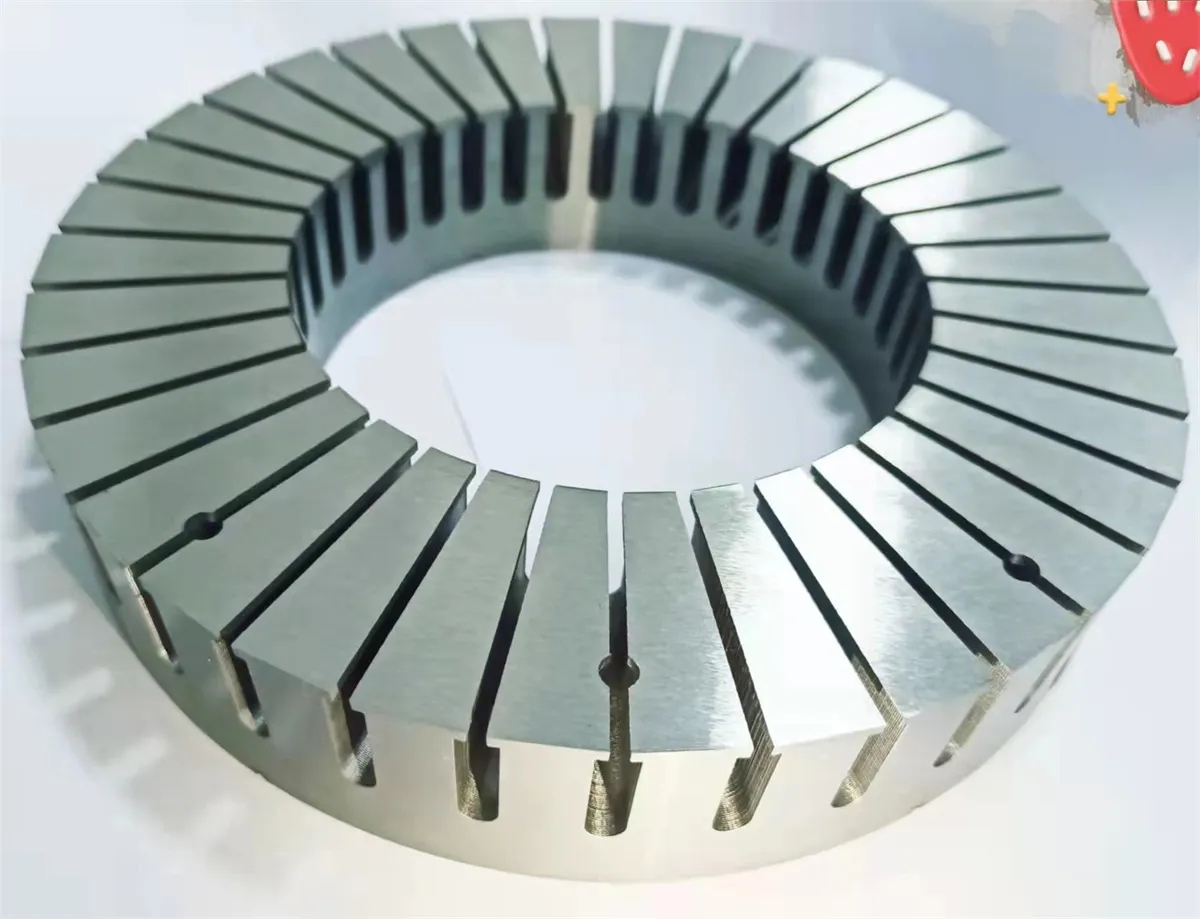

Rotor lamination stack |

Also made of multiple silicon steel sheets stacked together, but the shape and structure are different from the stator. The rotor lamination stack is usually fixed to the rotating shaft to form a rotating whole. There are magnetic steel slots on its surface for placing permanent magnets or excitation windings. |

2. Function:

|

Stator lamination stack |

Mainly responsible for generating a magnetic field, and connected to the power supply through winding coils to convert electrical energy into mechanical energy. |

|---|---|

|

Rotor lamination stack |

Rotor lamination stack: Rotates in the magnetic field generated by the stator, thereby realizing the conversion of electrical energy and mechanical energy. |

Production process

1. Stator lamination production process:

|

|

Select appropriate silicon steel sheet materials to ensure that they have excellent magnetic properties and magnetic conductivity. |

|---|---|

|

|

Use precision processing technologies such as laser cutting or stamping to cut silicon steel sheets into a predetermined shape. |

|

|

Insulate the cut silicon steel sheets to prevent short circuits between winding coils. |

|

|

Stack the processed silicon steel sheets together to form a solid cylinder. |

|

|

Slot the stacked stator core and embed the winding coils into it. |

2. Rotor lamination production process:

|

|

Also select appropriate silicon steel sheet materials. |

|---|---|

|

|

Use laser cutting or stamping to cut silicon steel sheets into a shape that matches the rotor. |

|

|

Insulate the silicon steel sheets to improve the overall performance of the rotor. |

|

|

Stack and fix the processed silicon steel sheets on the shaft. |

|

|

Open magnetic steel slots on the surface of the rotor core and place permanent magnets or excitation windings in them. |

The role of the stator and rotor stack in the motor

The role of the stator and rotor stack in the motor is crucial to the overall function of the motor. The main role of the stator stack is to generate a magnetic field. Due to its laminated design, the stator stack minimizes power losses and reduces vibration and noise, which helps improve the efficiency and function of the motor.

The rotor stack, on the other hand, responds to the magnetic field generated by the stator to produce the necessary mechanical rotation to generate electricity. Without a properly functioning rotor, the motor will not generate any electricity and thus become useless.

The most basic working principle of the stator and rotor stack is to generate rotational motion. When electrical energy is applied to the motor, it creates a magnetic field in the stator stack, which then causes the rotor to rotate. This action generates a mechanical force, which produces energy in the form of motion or rotation.

Common Applications for Stator and Rotor Lamination Stacks

Electric motors are used in a variety of applications, and laminated cores are essential. Some common applications include:

Industrial equipment and machinery

HVAC systems

Electric vehicles

Power tools

Kitchen appliances

Electric motors also play a key role in renewable energy systems such as wind turbines, where rotor laminates are essential for converting wind energy into electricity.

Our Capability For Stator And Rotor Lamination Stacks

We can design and manufacture a range of high-quality stator and rotor lamination stacks for electric motors, including stamping, die design and fabrication, and stacking. We ensure that every component we produce is manufactured to the highest standards, meeting our customers’ precise requirements.

With our expertise in motor components, we can provide custom solutions that meet our customers’ unique needs, ensuring their motors run efficiently. Whether you require high-volume production or custom components, we have the experience and capabilities to meet all your needs.

From stamping to insulation, bonding, assembly and quality testing, we offer a streamlined supply chain and short lead times for motor lamination prototypes and mass production.

Conclusion

In summary, the motor stator and rotor lamination stacks are two critical components to the operation of electric motors.

While their relative designs and materials may differ, their roles in generating magnetic fields and rotational forces to drive machinery and equipment are vital to industrial operations.

Understanding the differences between the two laminated components and their unique roles is essential to properly selecting and maintaining electric motors.

FAQS

What Are Lamination Stacks and How Are They Made?

Lamination stacks are often used as stators or rotors in generators or motors. They can also be used as laminated cores. Lamination stacks are often made from nickel-iron or cobalt-iron materials to optimize cost and wear resistance. Both nickel-based and cobalt-based materials are ideal for lamination stacks because they perform well in critical, heavy-duty applications such as automotive, aerospace, and military.

Once the alloy is decided, the laminations are laser cut, slotted, or punched depending on the volume to ensure accuracy. A stacking fixture is used to hold the laminations, which are then stacked to the correct height with a tolerance of +/- 1 layer. Precision gauge pins align each stack to an accuracy of up to +/- 0.02MM. Once the laminations are placed on the stacking fixture, they can be welded, riveted, or bonded together depending on the application.

What are the benefits of using a lamination stack?

Our cobalt and nickel iron, silicon steel materials can have laminations as thin as 0.05MM. This dimension is important because thinner layers have better resistance to eddy current losses. Without the lamination stack, eddy currents can generate a lot of heat, leading to poor performance and potential motor failure.

Youyou Company ensures strict quality control from raw materials to ready-to-use laminations. Our lamination stacks are an integral component in generators for aerospace, defense vehicles, medical devices, navigation systems, and more. We help you customize your lamination stacks to the specific materials or restrictions required for your application. We can also make prototypes for your approval before mass production of your project. In addition, we offer a variety of processing options through our grinding department.

What Are Common Materials Used In Motor Core Lamination Stacks?

When it comes to motor core lamination, electrical steel is the most common material that is used. This is because electrical steel has many magnetic properties that make it ideal for motor lamination.

These properties include high permeability, low coercivity, and high saturation flux density.

Other materials that can be used in motor core lamination include nickel alloy and cobalt alloy.

Bonding varnish (Backlack) Lamination - Act Now!

Bring unparalleled quality and performance to your products with our advanced lamination bonding solutions. Trust our expertise to enhance structural integrity, reduce vibration and optimize magnetic energy transfer. Contact us now!

You might also be interested in