The design and custom processing of axial flux motor stator lamination stacks is a comprehensive engineering technology involving multiple fields such as material science, electromagnetics, mechanical engineering and precision manufacturing. Here is an overview of some key points of the process:

1. Fase de projeto:

1.1 Magnetic circuit design

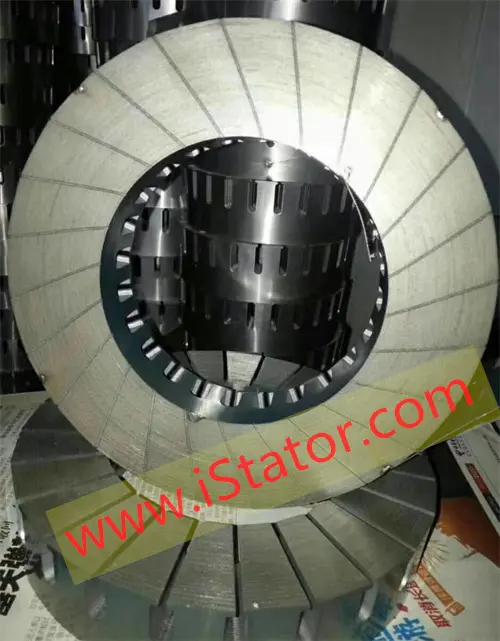

The characteristic of an axial flux motor is that its magnetic field is distributed along the axial direction. Therefore, when designing the stator laminations, it is necessary to accurately calculate the length of the magnetic circuit, the width of the air gap, and the shape and size of the laminations to optimize the motor's performance. Magnetic flux density and reluctance losses.

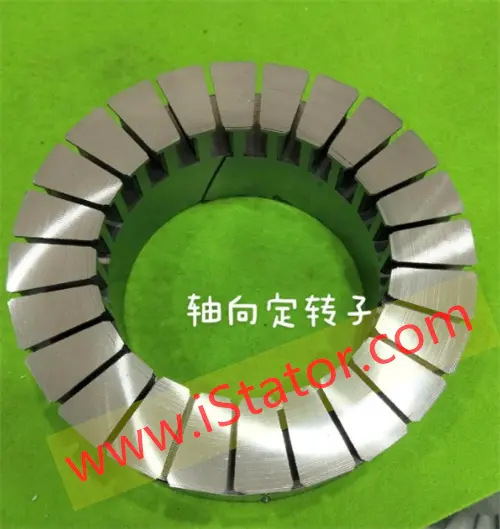

1.2 Lamination geometry

The laminations are usually made of silicon steel sheets. Their shape, thickness and lamination method (such as inclined groove, flat groove or mixed groove structure) will affect the performance and efficiency of the motor.

1.3 Insulation treatment

Insulation treatment is required between laminations to prevent short circuits. The selection and treatment of insulating materials are also an important part of the design.

2. Seleção de materiais:

2.1 Silicon steel sheet

Choose high-quality silicon steel sheet with high magnetic permeability and low loss characteristics to reduce iron loss during motor operation.

2.2 Insulation material

Choose insulating paint or film that is suitable for the operating temperature, has good mechanical properties and electrical insulation properties.

3. Lamination processing:

3.1 Stamping

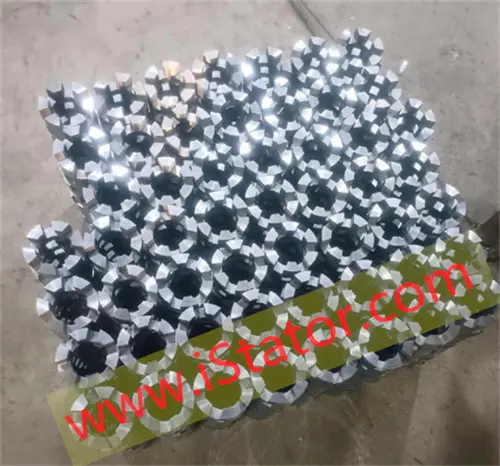

Use precision molds to stamp silicon steel sheets to ensure the dimensional accuracy of the laminations and the consistency of the groove structure.

3.2 Lamination stacking

The stamped silicon steel sheets are stacked in an orderly manner according to the design requirements. The gaps between the laminations are properly controlled, which can not only ensure the smooth flow of magnetic flux but also limit the eddy current loss.

4. Processamento personalizado:

4.1 Fixing process

The stack of laminates is fixed into one through welding, gluing or mechanical fastening to ensure the stability of the motor during operation.

4.2 Winding embedding

According to the motor design, the coil windings are accurately embedded into the lamination slots to form a complete electromagnetic circuit.

4.3 Quality inspection

Conduct comprehensive quality inspection on the custom-processed stator lamination stack, including but not limited to dimensional accuracy, surface quality, insulation performance and magnetic performance.

5. Otimização e simulação:

The motor design is optimized and simulated through finite element analysis (FEA) and other means to ensure that the final product meets the predetermined performance indicators.

In short, the design and custom processing of the axial flux motor stator lamination stack is a highly refined process that requires a combination of theoretical calculations, experimental verification, and advanced manufacturing technology to produce efficient, stable and specific applications. products in demand.

Dongguan Youyou Technology Co., Ltd. has many years of production capacity and manufacture axial stators using progressive stamping. Welcome to Contact our technology.