In modern industrial production, the motor serves as the core power device, and its internal stator and rotor components are key components that determine the performance of the motor. Among them, the iron cores of the stator and rotor adopt a precision manufacturing process called "stamping lamination". This article will analyze this process in depth and demonstrate the charm of the core laminated stamping manufacturing process, which is the core component of the motor stator and rotor.

1. Overview of stamping lamination process

The iron core of the motor stator and rotor is made of multi-layer silicon steel sheets through precision stamping and lamination technology. This process first selects high-quality silicon steel sheet materials with high magnetic permeability and low loss characteristics, and then stamps them through precision molds to form single-piece iron core laminations with specific shapes and notches or teeth.

2. Silicon steel sheet stamping process

2.1 Cutting and blanking

First, the entire roll of silicon steel strip is accurately cut according to the predetermined size to obtain the raw material of a single silicon steel sheet.

2.2 Precision Stamping

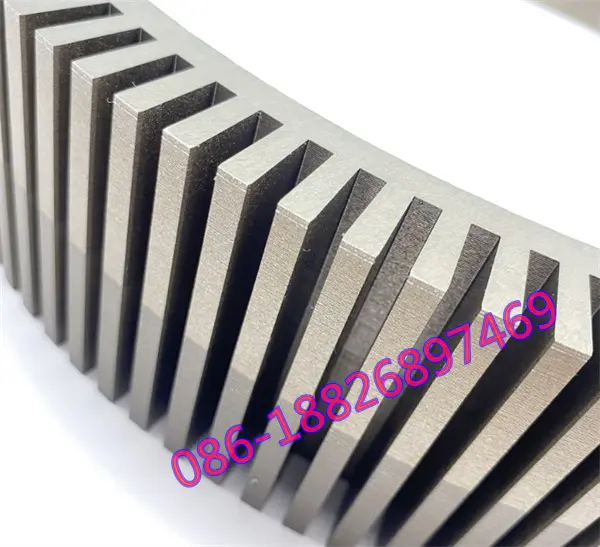

Use high-precision stamping dies to continuously stamp silicon steel sheets to form the complex structures required for the stator or rotor, such as the slot shape of the stator, the tooth shape of the rotor, etc., to facilitate coil winding and Magnetic field interaction.

2.3 Deburring

Burrs may be generated during the stamping process. In order to ensure the close fit between the laminations and the stability of the motor during operation, each silicon steel sheet needs to be deburred.

3. Lamination assembly

The stamped silicon steel sheets need to be stacked neatly in a specific order. There is usually a certain angle between adjacent silicon steel sheets. This is called "stepping". The purpose is to reduce eddy current losses and improve motor efficiency. Special adhesive or mechanical pressure is used to press and fix the stacked iron core to ensure that the overall structure is stable and reliable.

4. Summary

The laminated stamping manufacturing process of motor stator and rotor cores is a high-tech process that integrates material science, precision processing technology, and electromagnetic design theory. It can not only meet the needs of high efficiency and energy saving of the motor, but also determines the working performance and service life of the motor to a certain extent. With the advancement of science and technology, we have reason to believe that the future motor core manufacturing process will be leaner and smarter, providing solid technical support for the realization of higher quality, more energy-saving and environmentally friendly motor products.

You might also be interested in